Last week the graduating dental student presented their master projects. Our Sander Marius Landrø and Magnus Helgerud were nominated for their project for the Norwegian Dental Association (NDA) Student Research Prize. "Using Copper-Doped Mesoporous Bioactive Glass Nanospheres to Impart Anti-Bacterial Properties to Dental Composites". Marius and Magnus will present their research next autumn at the Norwegian Dental Association Conference.

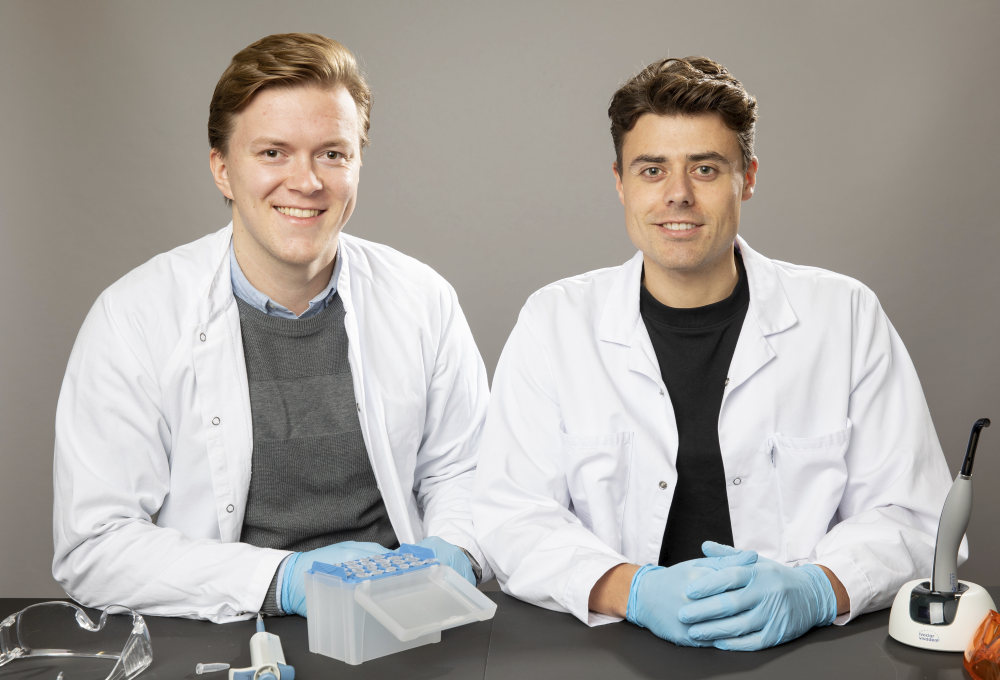

Master's students Sander Marius Landrø and Magnus Helgerud Master's students Sander Marius Landrø (left) and Magnus Helgerud. Photo: Marie Lindeman Johansen, OD/UiO

The results from Master's Thesis has already been published in the international journal Pharmaceutics.

"This doesn't happen often," says one of the supervisors Håvard Haugen. It's impressive! Arooj Munir and Liebert Nogueira were two other supervisors for the students.

"It's very exciting that the article published in the journal Pharmaceutics is based on the work we have done in the lab for our master's thesis," says Sander and Magnus.

Proud and satisfied master's students Last summer, Sander and Magnus were granted part-time scholarships of NOK 50,000 each from the Norwegian Research Council to work on their master's thesis. They have been working with the research results they use in their thesis at the department's research lab. The results they obtained are part of a project collaboration between IKO, IOB, and the universities in Zurich, Zagreb, and Erlangen.

"We have been involved in testing a new filling material made of a new bioglass developed by the University of Zagreb," Sander and Magnus explain.

"We received some boxes of composite or filling material for teeth. The composite was also supplemented with different filler particles that provide the material with antibacterial properties. Our task was to test the various physical properties of the composite."

Remarkable results

"We conducted different investigations in which we tested the degree of polymerisation, shrinkage and the material's porosity. We also used nano-CT to check the components of the material and how the particles are distributed within it," says Sander.

"We made small cylinders or clumps of the composite and tested their curing, i.e., the degree of polymerisation. Then we tried ion release, or how much-added substances are released when they come into contact with water. Specifically, we were interested in knowing which ions and how much of them are released in the mouth after filling a tooth.

"To check the degree of shrinkage in the material, we used nano-CT. We developed a new technique together with our supervisors, Liebert Nogueira, Arooj Munir, and Håvard Haugen," Magnus explains.

"We performed nano-CT scans of the composite clump before curing it, then scanned it again after curing. Arooj Munir helped us with the antibacterial testing.

"Then we measured the volume of the composite to see how much it had shrunk, where it had shrunk, and whether it shrunk on the outside or if there were pores inside the material.

"The most exciting part," Sander says, "was the results we obtained when measuring the degree of polymerisation, which indicates the strength and quality of the material. When we tested it, we achieved a degree of polymerisation of over 90%.

"And that was the highest our supervisor had ever seen. Usually, the degree of polymerisation is around 60-75%. Our supervisor didn't believe us, so he repeated all the measurements and obtained the same results.

"It is unique for the bioglass composite to have such a high degree of polymerisation. That is not common," Magnus says. "This will make such filling materials much stronger and longer-lasting than other materials. The project was very pleased with that!"

"It is unique for the bioglass composite to have such a high degree of polymerisation. That is not common," Magnus says. "This will make filling materials much stronger and longer-lasting than other materials. The project was very pleased with that!"

Master's students Sander Marius Landrø and Magnus Helgerud tested various physical properties of a new filling material made of bioglass. Photo: Marie Lindeman Johansen, OD/UiO

Recognised by outstanding researchers

Aldo Boccaccini and Thomas Attin are renowned names with which we are also proud to be associated. They read the article and were pleased and surprised by the results we obtained.

"Boccaccini and Attin have conducted significant research in the field of biomaterials. It's very exciting when the big names in the field notice what you're doing. They are also co-authors," Magnus and Sander explain.

"We have spent much time working on the project and teaching and reading course material. It's incredibly exciting that it resulted in this article in a renowned journal," says Sander and Magnus.

A future as a researcher?

"Now Sander and I are receiving numerous invitations to conferences and to write for journals," Magnus says.

So, a research career is in the future?

"I will definitely become a dentist first," Magnus says.

"But now we have a backup plan," adds Sander.

"All the results, tables, and graphs published in the article are from our work, but the credit goes to Danjiela Marovic, from the University of Zagreb for preparing and creating the material we tested."